Posts Tagged: food processing

World's first LEED Platinum winery, brewery and food-processing labs

The $20 million, 34,000-square-foot teaching-and-research complex is the first winery, brewery or food-processing facility expected to earn LEED Platinum certification, the highest environmental rating awarded by the U.S. Green Building Council. It is intended to become self-sustainable in energy and water use.

Neal Van Alfen, dean of the College of Agricultural and Environmental Sciences at UC Davis, said, "It will serve as a model for industries throughout the nation that are also committed both to environmental excellence and production efficiency."

The complex houses a brewery, general foods-processing plant, milk-processing laboratory, and a teaching-and-research winery which will serve as a test bed for production processes that conserve water, energy, and other resources. The complex is adjacent to a 12-acre teaching-and-research vineyard.

Its environmentally friendly features include on-site solar power generation, a large-capacity system for capturing rainwater and conserving processing water, and many other features. The facility is expected to be carbon zero in carbon emissions.

Read more about the facility and take an online tour at the facility’s website.

A new era begins in food and beverage science

A new winery, brewery and food-processing complex began operations this fall at UC Davis. Part of the Robert Mondavi Institute for Wine and Food Science, the technologically sophisticated facilities will be used to teach students, conduct research, and solve practical problems related to foods, beverages and health.

The south wing of the new complex is home to the August A. Busch III Brewing and Food Science Laboratory, which includes the brewery, general foods-processing plant and milk-processing laboratory. The complex’s north wing houses a new teaching-and-research winery. The complex is adjacent to a 12-acre teaching-and-research vineyard and across a courtyard from the departments of Food Science and Technology, and Viticulture and Enology.

The new $20 million, 34,000-square-foot complex, funded entirely by private donations, will be the first winery, brewery and/or food-processing facility to earn LEED Platinum certification, the highest environmental rating awarded by the U.S. Green Building Council. (LEED stands for Leadership in Energy and Environmental Design.)

Features include onsite solar power generation and a system for capturing rainwater and conserving processing water. Stored rainwater will be used for landscaping and toilets.

Other features include maximum use of natural light, food-processing equipment that minimizes energy and water requirements, use of recycled glass in flooring, interior paneling recycled from a 1928 wooden aqueduct, and use of sustainably certified lumber.

The new brewery will showcase the latest in brewing technology, as well as a sophisticated laboratory for conducting research and training students. It also provides commercial brewers and suppliers with a small-scale facility to test new recipes or processes.

The general foods- and milk-processing laboratories have been built to meet state and federal food- and dairy-grade standards. Products processed there will be used in sensory and nutritional evaluations.

Research in the food-processing pilot plant will examine alternative food-processing methods and their nutritional effects, nutritional quality and shelf life of fresh-cut fruits and vegetables, nutritional enhancements from food-processing “waste” products, and improved food formulations.

The milk-processing laboratory will support research on separation of milk components into functional ingredients, processing of milk modified by different feed rations, and processing of milk from cows bred for specific characteristics.

Dozens of private donors helped make the complex a reality, including a $5 million contribution from the late winemaker, Robert Mondavi, and a $5 million pledge by the Anheuser-Busch Foundation.

Other major donations were made by Ronald and Diane Miller and by a group of winery partners led by Jess Jackson and Barbara Banke of Kendall-Jackson Wines, and Jerry Lohr of J. Lohr Vineyards & Wines. The Department of Viticulture and Enology’s Board of Visitors and Fellows also made significant contributions.

California tomato processors and growers contributed more than $2.5 million to the food-processing pilot plant. Morning Star Packing Company provided a lead gift of $1 million for the food-processing plant. Hilmar Cheese Company also stepped up with a $250,000 pledge.

In all, more than 150 individuals, alumni, corporations and foundations contributed funds for the new winery, brewery and food-processing complex.

(Thanks to Patricia Bailey, UC Davis News Service, who provided content for this post.)

Learn more at http://greenrmi.ucdavis.edu.

Reducing water use in food processing

Two methods are used to remove skins in processed tomatoes — a hot water/lye dip, or steam. The dip method uses a lot of water, a lot of energy, and creates a lot of salts . . . which presents its own disposal problem. Steam treatment heats too much of the tomato, resulting in reduced yield and quality.

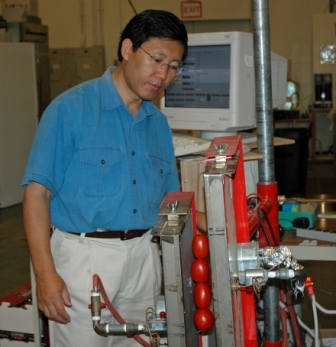

“The tomato processing industry has long been interested in finding a better way of peeling tomatoes,” says Dr. Zhongli Pan, a USDA researcher, and an adjunct professor at UC Davis. He found that peeling tomatoes with infrared heat eliminates lye use, greatly reduces water use, and results in better quality tomatoes.

Infrared heat is similar to heat from the sun and fireplaces. It allows for efficient heat transfer from the source to the product. Infrared heat has promising potential not only for dry-peeling tomatoes, peaches, and other produce, but also for blanching many fruits and vegetables before freezing, such as apples and “baby” carrots.

Pan and his colleagues are building a pilot-scale infrared tomato heating device. The goal is to develop commercial-scale guidelines for peeling tomatoes and other products with infrared heat. As California's water resources dwindle, new technologies such as this should reduce our reliance on water.

Higher-quality pizza and tomato sauces, and many other food products may appear on our tables if infrared heat can be adopted by the food-processing industry. The secondary impact on water conservation will benefit us all.

(This article was condensed from UC Davis’ “CA&ES Outlook” magazine, fall/winter 2009, page 10.)